Chiller Plant Optimization System (CPOS): Enhancing Cooling Efficiency

CPOS (Chiller Plant Optimization Systems) are essential for data centers, where maintaining precise temperatures is crucial for equipment reliability and performance. These systems utilize advanced algorithms and sensors to monitor and control various factors, such as refrigerant flow, water temperature, and compressor efficiency. By optimizing the chiller plant’s operation, data centers can significantly reduce energy consumption, lower operational costs, and improve overall sustainability. These systems often incorporate features like load shedding, free cooling, and predictive maintenance to ensure optimal performance and minimize downtime.

Purpose and Function:

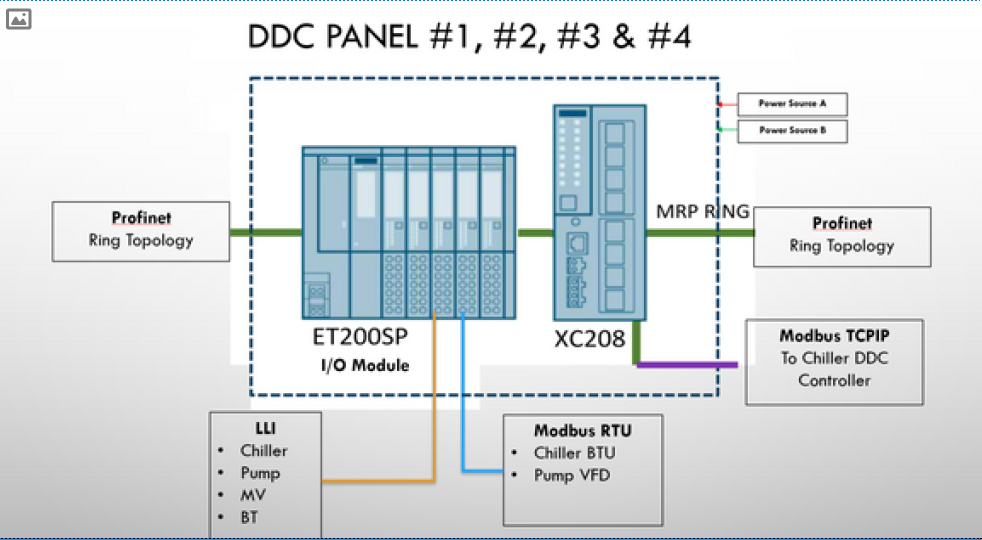

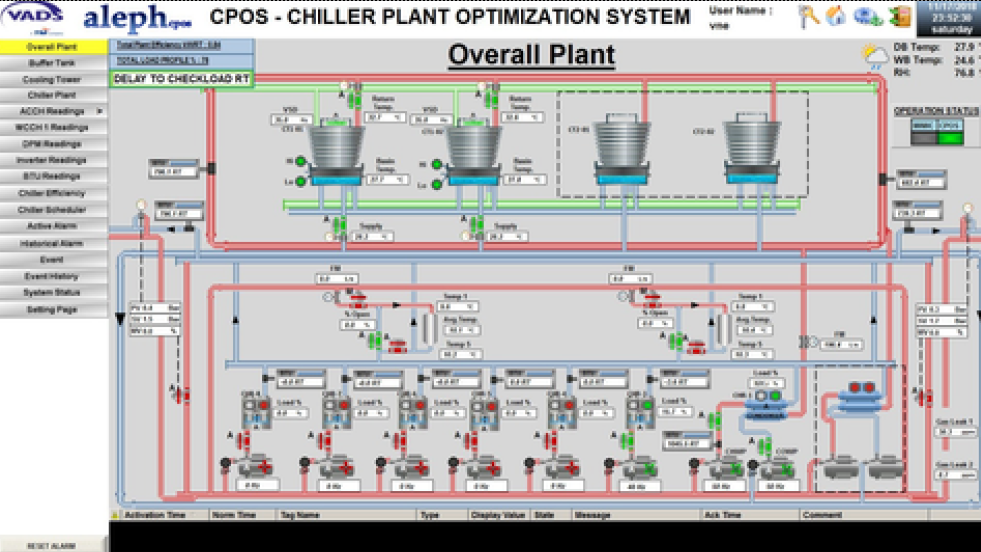

- CPOS optimizes the operation of water-cooled centrifugal or air-cooled chilled water plants.

- It holistically monitors and controls five interdependent systems: cooling towers, condenser pumps, chillers, chilled water pumps, and air-handling units

Key Goals:

- Energy Reduction: CPOS aims to minimize energy consumption by optimizing system performance.

- Reliability Enhancement: By maintaining optimal differential system pressure and managing chiller lift, CPOS ensures reliable operation even under varying loads.

- Cost Savings: Lower operational costs are achieved through efficient control strategies

In summary, a well-implemented CPOS not only enhances cooling efficiency but also contributes to sustainability and cost-effectiveness in building operations.

Key Features of Chiller Plant Optimization System (CPOS)

Advanced Control Algorithms:

- CPOS employs sophisticated algorithms to optimize chiller plant operation.

- These algorithms dynamically adjust system parameters, ensuring efficient performance and load balancing.

Real-Time Monitoring:

- CPOS continuously monitors chiller plant performance and operating conditions.

- Real-time data allows for proactive adjustments and rapid response to changing demands.

Energy Efficiency:

- By intelligently adjusting chiller operation, CPOS minimizes energy consumption.

- It optimizes cooling output while maintaining reliability and comfort.

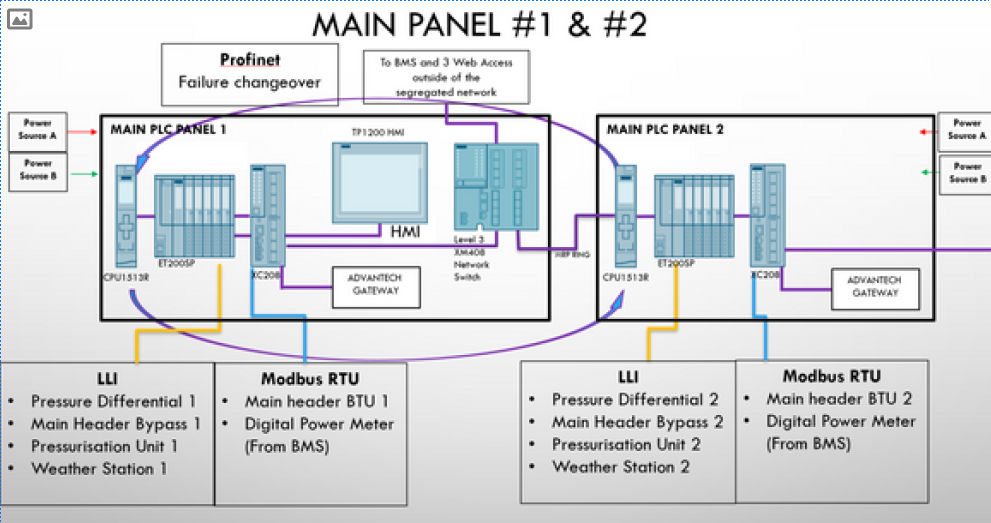

BMS Integration:

- CPOS seamlessly integrates with Building Management Systems (BMS).

- This integration streamlines control, data exchange, and overall facility management.

In summary, a well-implemented CPOS enhances energy savings, reliability, and operational efficiency in chiller plants.

The revitalized art gallery is set to redefine cultural landscape.

Benefits of CPOS

Energy Savings:

- CPOS significantly reduces energy consumption, leading to lower utility bills.

- Efficient chiller plant operation translates to cost savings and environmental benefits.

Operational Efficiency:

- By optimizing system performance, CPOS ensures reliable chiller plant operations.

- Improved efficiency minimizes downtime and enhances overall reliability.

Enhanced Control:

- CPOS provides better control and flexibility in managing cooling requirements.

- Real-time adjustments optimize performance based on varying loads.

Cost Savings:

- Optimized performance and predictive maintenance reduce operational costs.

- Maintenance schedules align with actual needs, avoiding unnecessary expenses.

Environmental Impact:

- Decreased energy use directly lowers greenhouse gas emissions.

- CPOS contributes to sustainability and environmental responsibility.

In summary, implementing CPOS delivers a holistic approach to efficient, reliable, and eco-friendly chiller plant management.